ABOUT US

Zhong Xiang Precision Machinery Co., Ltd., located in Dali District, Taichung City, founded in 1995, with 30 years of manufacturing experience and a fleet of 16 CNC machining centers (including 6 horizontal and 10 vertical). Adhering to the core philosophy of "Stable as Chung, Flexible as Chung," we combine a solid technical foundation with a flexible and innovative spirit to provide high-quality, flexible contract manufacturing services. Zhong Xiang's focus on machining details and quality control has earned the trust of numerous publicly listed companies, and we are committed to creating win-win situations with our customers.

HOT NEWS

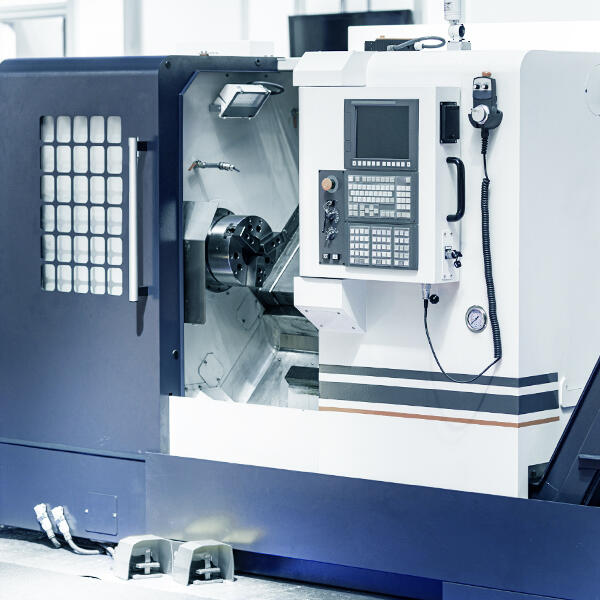

CNC Vertical Machining Center

ZhongXiang has 10 high-rigidity and high-stability CNC Vertical Machining Centers with a maximum machining stroke of 1400×800mm. They can accurately perform various types of metal milling with stable machining quality to meet the needs of various industries.

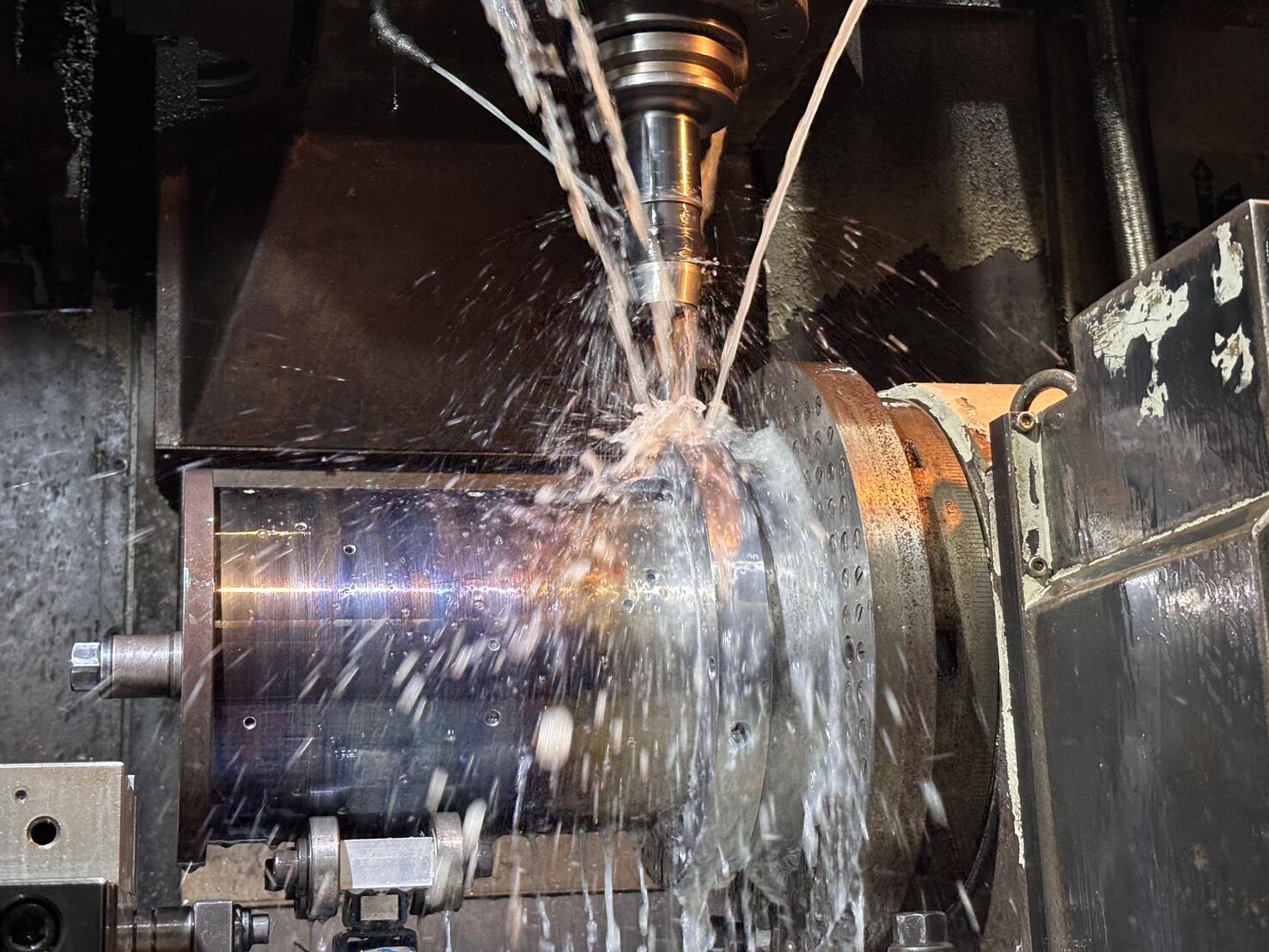

CNC Horizontal Machining Center

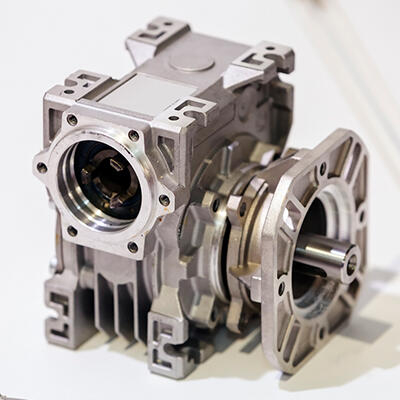

Zhongxiang is equipped with 6 CNC Horizontal Machining Centers, with maximum table diameter of 800 x 800 mm, suitable for machining complex parts such as motor housings, bearing bores, and worm gears. Equipped with a B-axis rotary table, they can complete multi-surface machining in a single clamping, effectively improving the precision and efficiency of mass production.

3D Coordinate Measuring Machine (CMM)

ZhongXiang strictly controls machining accuracy throughout the entire production process and conducts inspections using the Keyence 3D Coordinate Measuring Machine (XM-5000), ensuring consistent, stable, and fully traceable product quality.

Metal Material Processing

Zhongxiang has extensive manufacturing experience and is able to process a variety of materials, including castings, iron, aluminum, copper, and bakelite. We select the most appropriate processing method based on the characteristics of the material to ensure that our products meet high quality standards.

Processable Materials

Zhongxiang provides one-stop service. We can produce materials according to customer needs, flexibly integrate upstream and downstream resources, effectively shorten delivery time and reduce costs. A professional team will assist in material selection and provide suggestions to accurately meet customer needs.

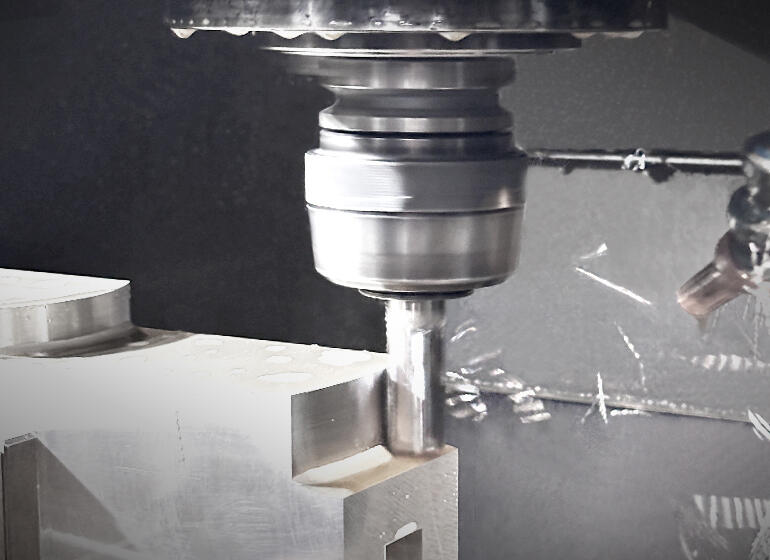

General Processing

CNC milling and lathe processing.